Material Composition

The primary components of deep groove ball bearings are typically crafted from high-grade chrome steel (such as AISI 52100), a material chosen for its exceptional hardness, wear resistance, and fatigue strength after heat treatment. This ensures the bearings can withstand continuous operation under varying load conditions. For applications requiring corrosion resistance—such as in food processing or marine environments—stainless steel (e.g., AISI 440C) is often used. The cages that separate and guide the balls are commonly made from brass, polyamide (nylon), or steel, depending on factors like speed, temperature, and load capacity.

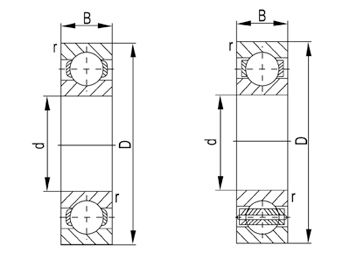

Structural Design

A standard deep groove ball bearing consists of four key components: an outer ring, an inner ring, a set of steel balls, and a cage. The inner and outer rings feature continuous, deep raceways with a groove radius slightly larger than the radius of the balls. This unique groove design allows the bearing to accommodate radial loads as well as moderate axial loads from both directions. The cage maintains uniform spacing between the balls, preventing friction and collision between them during rotation, which in turn reduces heat generation and improves efficiency. Unlike angular contact ball bearings, deep groove ball bearings have no intentional contact angle, enabling them to operate at higher speeds.

Key Characteristics

High Versatility: They can handle both radial and axial loads, eliminating the need for separate thrust bearings in many applications.

High-Speed Capability: The simple structure and optimized raceway design minimize friction, allowing them to operate at high rotational speeds.

Low Maintenance: Due to their sealed designs (in many variants), they require minimal lubrication and upkeep, even in harsh environments.

Cost-Effective: Compared to specialized bearings, deep groove ball bearings are relatively inexpensive to manufacture, making them a cost-efficient choice for general-purpose use.

Easy Installation: Their standardized dimensions and straightforward design simplify mounting, reducing assembly time and complexity.

Applications

Deep groove ball bearings are ubiquitous across industries due to their adaptability. In the automotive sector, they are used in wheel hubs, transmissions, and electric motor assemblies. In household appliances, they can be found in washing machines, fans, and power tools, where smooth and quiet operation is essential. The industrial machinery field relies on them for conveyor systems, pumps, and compressors. Additionally, they play a critical role in electrical equipment such as generators and electric motors, where their high-speed performance and durability are paramount. Even in precision instruments like medical devices and robotics, smaller-sized deep groove ball bearings are valued for their reliability and compact design.

Types

Basic type; With snap ring groove on the outer ring (-N); With one shield (-Z) on one side or two shields (-2Z) on both sides; With one seal (-RS) on one side or two seals (-2RS) on both sides.

| Bearing No. | Boundary dimensions | Basic load ratings (kN) | Limiting speed | Mass |

| mm | Dynamic | Static | rpm | Kg |

| d | D | B | rs min | Cr | Cor | Grease | Oil | ≈ |

| 6200 | 10 | 30 | 9 | 0.6 | 5.1 | 2.38 | 25000 | 30000 | 0.032 |

| 6201 | 12 | 32 | 10 | 0.6 | 6.82 | 3.05 | 22000 | 26000 | 0.035 |

| 6202 | 15 | 35 | 11 | 0.6 | 7.65 | 3.72 | 19000 | 23000 | 0.045 |

| 6203 | 17 | 40 | 12 | 0.6 | 9.58 | 4.78 | 18000 | 21000 | 0.064 |

| 6204 | 20 | 47 | 14 | 1 | 12.8 | 6.65 | 16000 | 18000 | 0.103 |

| 6205 | 25 | 52 | 15 | 1 | 14 | 7.88 | 13000 | 15000 | 0.127 |

| 6206 | 30 | 62 | 16 | 1 | 19.5 | 11.5 | 11000 | 13000 | 0.200 |

| 6207 | 35 | 72 | 17 | 1.1 | 25.5 | 15.2 | 9800 | 11000 | 0.288 |

| 6208 | 40 | 80 | 18 | 1.1 | 29.5 | 18 | 8700 | 10000 | 0.368 |

| 6209 | 45 | 85 | 19 | 1.1 | 31.5 | 20.5 | 7800 | 9200 | 0.416 |

| 6210 | 50 | 90 | 20 | 1.1 | 35 | 23.2 | 7100 | 8300 | 0.463 |

| 6211 | 55 | 100 | 21 | 1.5 | 43.4 | 29.4 | 6400 | 7600 | 0.607 |

| 6212 | 60 | 110 | 22 | 1.5 | 52.4 | 36.2 | 6000 | 7000 | 0.783 |

| 6213 | 65 | 120 | 23 | 1.5 | 57.2 | 40.1 | 5500 | 6500 | 0.990 |

| 6214 | 70 | 125 | 24 | 1.5 | 62.2 | 44.1 | 5100 | 6000 | 1.070 |

| 6215 | 75 | 130 | 25 | 1.5 | 67.4 | 48.3 | 4800 | 5600 | 1.180 |

| 6216 | 80 | 140 | 26 | 2 | 72.7 | 53 | 4500 | 5300 | 1.400 |

| 6217 | 85 | 150 | 28 | 2 | 84 | 61.9 | 4200 | 5000 | 1.790 |

| 6218 | 90 | 160 | 30 | 2 | 96.1 | 71.5 | 4000 | 4700 | 2.150 |

| 6219 | 95 | 170 | 32 | 2.1 | 109 | 81.9 | 3700 | 4400 | 2.620 |

| 6220 | 100 | 180 | 34 | 2.1 | 122 | 93.1 | 3500 | 4200 | 3.140 |

| 6221 | 105 | 190 | 36 | 2.1 | 133 | 105 | 3400 | 4000 | 3.700 |

| 6222 | 110 | 200 | 38 | 2.1 | 144 | 117 | 3200 | 3800 | 4.360 |

| 6224 | 120 | 215 | 40 | 2.1 | 155 | 131 | 2900 | 3400 | 5.150 |

| 6226 | 130 | 230 | 40 | 3 | 167 | 146 | 2700 | 3100 | 5.820 |

| 6228 | 140 | 250 | 42 | 3 | 166 | 150 | 2500 | 2900 | 7.570 |

| 6230 | 150 | 270 | 45 | 3 | 176 | 168 | 2300 | 2700 | 9.410 |

| 6232 | 160 | 290 | 48 | 3 | 185 | 186 | 2100 | 2500 | 11.700 |

| 6234 | 170 | 310 | 52 | 4 | 212 | 223 | 2000 | 2400 | 14.500 |

| 6236 | 180 | 320 | 52 | 4 | 227 | 241 | 1900 | 2200 | 15.100 |

| 6238 | 190 | 340 | 55 | 4 | 255 | 281 | 1800 | 2100 | 18.200 |

| 6240 | 200 | 360 | 58 | 4 | 269 | 310 | 1700 | 2000 | 21.600 |

| 6244 | 220 | 400 | 65 | 4 | 297 | 365 | 1500 | 1800 | 30.200 |