1. Material Composition

Ring Material

The inner and outer rings of the MR41X bearing are typically crafted from 52100 chrome steel. This material is renowned for its high hardness, excellent wear resistance, and good fatigue strength. The use of 52100 chrome steel ensures that the bearing can withstand the rigors of continuous operation, even in high-stress environments. It has a Rockwell hardness of around 60-65 HRC, which provides a robust structure to support the rolling elements and resist deformation under load.

Ball Material

The balls within the MR41X bearing are also made from 52100 chrome steel. This consistent material choice for both the rings and balls promotes optimal compatibility in terms of hardness and wear characteristics. The high-quality chrome steel balls have a smooth surface finish, which reduces friction during rotation and contributes to the bearing's low noise operation. The material's fatigue resistance allows the balls to endure repeated loading cycles, extending the overall lifespan of the bearing.

Cage Material

In many MR41X bearings, the cage is often constructed from 300 series stainless steel. Stainless steel offers corrosion resistance, which is crucial in applications where the bearing may be exposed to moisture or corrosive substances. The cage's role is to keep the balls evenly spaced, guiding their movement and preventing them from colliding with each other. The 300 series stainless steel cage provides the necessary strength and flexibility to perform this function effectively, even at high speeds.

2. Design Features

Compact Dimensions

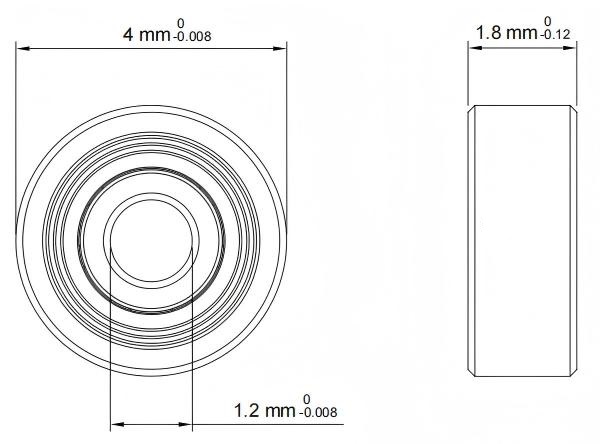

The MR41X bearing is characterized by its extremely compact dimensions. With an inner diameter of 1.2 mm, an outer diameter of 4 mm, and a width of 1.8 mm, it is specifically engineered for applications where space is severely limited. This small size makes it an ideal choice for miniature and micro-mechanical devices, such as those found in medical instruments, precision optical equipment, and small electric motors.

Deep Groove Design

It features a deep groove design, which is a common and highly effective configuration in ball bearings. The deep grooves on both the inner and outer rings provide a larger contact area for the balls. This design allows the bearing to accommodate both radial and axial loads with relative ease. The geometry of the deep grooves also helps to maintain the proper alignment of the balls during rotation, enhancing the bearing's stability and reducing the risk of ball skidding or misalignment.

Open Seal Type (Standard)

The standard MR41X bearing comes with an open seal type. This means that the bearing is not enclosed by additional seals on either side. The open design allows for easy access to the internal components, which can be beneficial for applications where regular lubrication or inspection is required. It also reduces the overall weight and size of the bearing slightly. However, in environments with high levels of contaminants, additional external sealing mechanisms may need to be employed to protect the bearing from debris and ensure its long-term performance.

High-Speed Capabilities

The MR41X bearing is designed to operate at high speeds. The combination of its smooth-rolling 52100 chrome steel balls, precision-machined raceways, and optimized cage design enables it to achieve high rotational speeds with minimal friction and heat generation. This makes it suitable for applications such as high-speed spindles in small machine tools, dental handpieces, and some types of turbochargers where rapid rotation is essential.

Low Friction and Reduced Noise

The smooth surface finish of the bearing components, along with the carefully selected materials and precise manufacturing tolerances, contribute to its low friction characteristics. Reduced friction not only improves the bearing's energy efficiency but also helps to minimize heat generation during operation. Additionally, the optimized design of the bearing, including the ball-raceway interaction and cage movement, results in reduced noise levels. This makes the MR41X bearing particularly suitable for applications where quiet operation is a requirement, such as in audio equipment, office machinery, and some medical devices.

3. Applications

Medical Field

• Miniature Pumps: In portable medical infusion pumps, the MR41X bearing's small size and high precision are essential. These pumps need to deliver precise amounts of medication at a controlled rate, and the bearing's ability to operate smoothly and quietly ensures accurate dosing.

• Diagnostic Equipment: In microscopes and other diagnostic imaging devices, the MR41X bearing is used in the focusing mechanisms. Its compact design allows for the construction of smaller, more portable imaging equipment, while its high rotational accuracy ensures clear and sharp images.

• Implantable Devices: Although its use in implantable devices is more limited due to strict biocompatibility requirements, in some cases, the MR41X bearing or similar miniature bearings may be used in components of implantable drug delivery systems or small mechanical actuators within the body. However, in such applications, the bearing materials may need to be further treated or coated to meet biocompatibility standards.

Electronics and Precision Instruments

• Hard Disk Drives: In the spindle motors of hard disk drives, the MR41X bearing plays a crucial role. It enables the high-speed rotation of the disk platters while maintaining precise positioning of the read/write heads. The bearing's low friction and high-speed capabilities are essential for ensuring fast data access and reliable operation of the hard disk drive.

• Optical Equipment: In cameras, projectors, and optical scanners, the MR41X bearing is used in the lens adjustment mechanisms. Its compact size allows for the design of more compact and lightweight optical equipment, while its smooth operation ensures accurate focusing and zooming functions.

• MEMS Devices: Micro-Electro-Mechanical Systems (MEMS) often require miniature bearings for their moving parts. The MR41X bearing can be used in MEMS gyroscopes, accelerometers, and other MEMS sensors to enable precise rotational or linear movements. Its small size and high precision are well-suited to the miniaturized nature of MEMS devices.

Aerospace and Defense

• Guided Missiles and UAVs: In the guidance systems of guided missiles and unmanned aerial vehicles (UAVs), the MR41X bearing may be used in components such as gyroscopes and servo motors. These bearings need to operate reliably in harsh environments, including high g-forces and varying temperatures. The MR41X bearing's high-quality materials and robust design make it suitable for such demanding applications.

• Satellite Instruments: In satellite-borne instruments, space is extremely limited, and weight is a critical factor. The MR41X bearing's compact size and lightweight construction make it an attractive option for use in mechanisms such as solar panel deployment systems, telescope pointing mechanisms, and data storage devices on satellites. Its ability to operate in a vacuum and withstand radiation also makes it suitable for space applications.

Consumer Goods

• Watches and Clocks: In high-precision mechanical watches and clocks, the MR41X bearing can be used in the escapement mechanism or the gear train. Its small size and smooth operation contribute to the accurate timekeeping of these timepieces. The bearing's low friction helps to reduce the power consumption of the watch movement, extending the battery life in quartz watches or reducing the frequency of winding in mechanical watches.

• Toys and Hobby Equipment: In small, high-performance toys such as miniature racing cars or helicopters, the MR41X bearing can be used in the motors and drive trains. Its compact size allows for the creation of more detailed and realistic miniature vehicles, while its high-speed capabilities enable these toys to achieve impressive performance levels.

| Part Number | MR41X |

| Characteristics |

| System of Measurement | Metric |

| Bearing Type | Ball |

| Seal Type | Open |

| Inner Ring Type | Standard |

| For Load Direction | Radial |

| Construction | Single Row |

| Ball Qty | 7 |

| Tolerance Class | ABEC1 |

| Dimensions |

| Bore Dia | 1.2 mm |

| Bore Dia Tolerance | -0.008mm to 0 |

| Outer Dia | 4 mm |

| Outer Dia Tolerance | -0.008mm to 0 |

| Width | 1.8 mm |

| Width Tolerance | -0.12mm to 0 |

| Ball Dia | 0.6 mm |

| Radial Clearance | 0.005mm to 0.01 mm |

| Radial Clearance Trade No | MC3 |

| Material |

| Ring Material | Chrome Steel |

| Ball Material | Chrome Steel |

| Cage Material | Carbon Steel |

| Performance |

| Dynamic Radial Load | 25 lbf |

| Static Radial Load | 7 lbf |

| Max Speed (X1000 rpm) | 105 |

| Temperature Range | -30° to 110 °C |

| Properties |

| Lubrication | Required |

| RoHS | Compliant |

| REACH | Compliant |

| Weight | 0.11 g |