Material

1. Ring Material: The ring of the S691 bearing is typically made of 440C stainless steel. This material offers excellent corrosion resistance, making it suitable for use in environments where moisture, chemicals, or other corrosive substances are present. For example, in medical equipment where sterilization processes involve exposure to various cleaning agents, the 440C stainless steel ring can withstand the harsh conditions without rusting or deteriorating. Additionally, 440C stainless steel has high hardness, which contributes to the bearing's durability and load - carrying capacity.

2. Ball Material: The balls inside the S691 bearing are also made of 440C stainless steel. The use of the same high - quality stainless steel for the balls ensures compatibility with the rings and consistent performance. The smooth surface finish of the 440C stainless steel balls reduces friction during rotation, enabling the bearing to operate quietly and efficiently. This is crucial in applications such as precision instruments where noise and smooth operation are of utmost importance.

3. Cage Material: The cage of the S691 bearing is usually made of 300 series stainless steel. The cage serves to separate the balls evenly, maintaining proper ball spacing and preventing them from colliding with each other. The 300 series stainless steel cage combines good corrosion resistance with sufficient strength and flexibility. It can withstand the centrifugal forces generated during high - speed rotation while keeping the balls in place, thus ensuring the stable operation of the bearing.

Design and Structure

The S691 bearing features a single - row ball configuration with a deep groove raceway in the outer ring. The deep groove design allows for higher radial load capacity compared to some other bearing types. It can effectively support radial forces acting on the shaft, making it suitable for applications where the main load is in the radial direction. For instance, in small electric motors, the S691 bearing can handle the radial forces generated by the rotation of the rotor, ensuring smooth operation of the motor.

Applications

1. Medical Equipment: In medical devices like insulin pumps, the S691 bearing's small size and corrosion - resistant properties are highly valued. The precise and smooth rotation provided by the bearing ensures accurate dosing of insulin, which is crucial for the well - being of diabetes patients. Additionally, in surgical instruments such as microsurgical forceps, the bearing's ability to operate quietly and with minimal friction is essential for delicate procedures.

2. Precision Instruments: In devices like atomic force microscopes, which require extremely precise movement and positioning, the S691 bearing plays a vital role. Its high - quality materials and accurate manufacturing tolerances enable it to support the delicate components of the microscope, ensuring stable and accurate measurements. In watches, the S691 bearing can be used in the movement to provide smooth and accurate timekeeping.

3. Miniature Motors: Small electric motors used in various applications, such as those in mobile devices for vibration motors or in small fans for cooling electronics, often rely on the S691 bearing. The bearing's ability to handle the radial loads generated by the motor's rotation and its high - speed capabilities contribute to the efficient and reliable operation of these motors.

| Part Number | S691 |

| System of Measurement | Metric |

| Bearing Type | Ball |

| For Load Direction | Radial |

| Construction | Single Row |

| Inner Ring Type | Standard |

| Seal Type | Open |

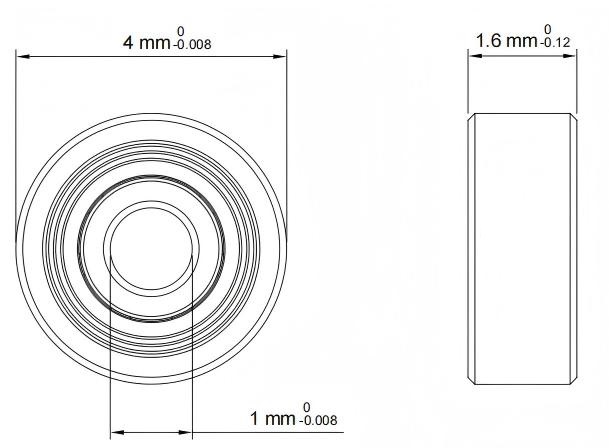

| Bore Dia | 1 mm |

| Bore Dia Tolerance | -0.008mm to 0 |

| Outer Dia | 4 mm |

| Outer Dia Tolerance | -0.008mm to 0 |

| Width | 1.6 mm |

| Width Tolerance | -0.12mm to 0 |

| Ring Material | Stainless Steel |

| Ball Material | Stainless Steel |

| Cage Material | Stainless Steel |

| Dynamic Radial Load | 24 lbf |

| Static Radial Load | 6 lbf |

| Max Speed (X1000 rpm) | 90 |

| Lubrication | Required |

| Temperature Range | -30° to 110 °C |

| Tolerance Class | ABEC1 |

| Radial Clearance Trade No | MC3 |

| Radial Clearance | 0.005mm to 0.01 mm |

| RoHS | Compliant |

| REACH | Compliant |

| Ball Dia | 0.8 mm |

| Ball Qty | 5 |

| Weight | 0.11 g |