Material

The S681 bearing is crafted with high - quality stainless steel, typically AISI 440C (9Cr18). This type of stainless - bearing steel endows the bearing with remarkable corrosion - resistance. It can withstand exposure to moisture, chemicals, and other corrosive agents, making it suitable for use in harsh environments. Both the inner and outer rings, as well as the balls and the cage (if present), are made of stainless steel. This uniform material selection ensures the bearing's durability and reliability over an extended service life. The stainless - steel balls offer smooth rolling motion, reducing friction and wear during operation. The cage, if there is one, helps to maintain the proper spacing between the balls, enhancing the bearing's stability and performance.

Design Features

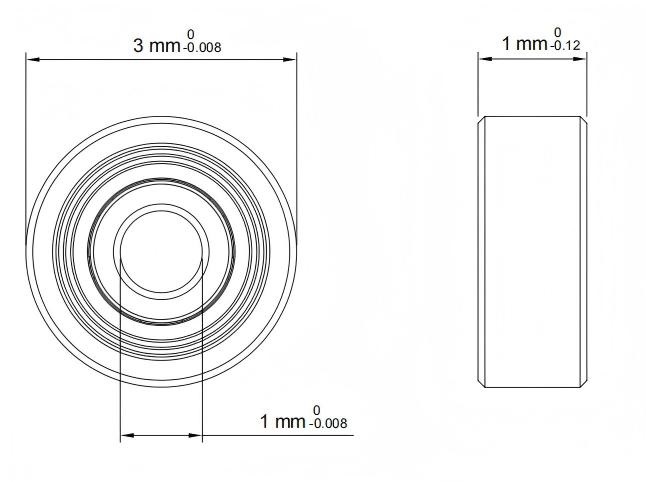

This bearing features a deep - groove ball design. The deep - groove raceway in the outer ring and the corresponding inner - ring raceway are precisely machined to provide a stable and smooth path for the balls. The single - row ball arrangement allows for efficient handling of radial loads. With a bore diameter of 1 mm, an outer diameter of 3 mm, and a width of 1 mm, the S681 is designed to fit into extremely tight spaces. It has a relatively light weight, approximately 0.03 g, which is beneficial for applications where minimizing mass is essential. The bearing is available in an open - type configuration, which means it has no built - in seals or shields. This open design allows for easy access to the internal components for lubrication and inspection. However, in environments with high levels of contaminants, additional external protection or more frequent maintenance may be required.

Applications

1. Medical Devices: In the medical field, the S681 bearing finds applications in devices such as pulmonary assist devices. Its small size and high precision are crucial for ensuring the smooth and reliable operation of components within these life - saving devices. The corrosion - resistance of the stainless - steel material is also vital as medical devices need to maintain their integrity even in environments where they may come into contact with bodily fluids or cleaning agents.

2. Precision Instruments: For instruments like clocks and certain types of scientific instrumentation, the S681 bearing's ability to operate with low friction and high precision is highly valued. In clocks, it helps to ensure accurate timekeeping by enabling smooth and consistent rotation of the gears. In scientific instruments, such as micro - positioning devices, the bearing's compact size and precise movement capabilities contribute to the accurate functioning of the equipment.

3. Miniature Mechanical Devices: Due to its small dimensions, the S681 is widely used in various miniature mechanical devices. For example, in jewelry spinning rings, the bearing allows for smooth and continuous rotation, enhancing the user experience. It is also used in small - scale motors, where its ability to handle high - speed rotation with minimal vibration is essential for the efficient operation of the motor.

4. Surveillance and Aerospace - related Applications: In some surveillance systems, especially those with compact designs, the S681 bearing can be used to facilitate the movement of camera components, enabling smooth panning and tilting. In aerospace applications, where space and weight are at a premium, the bearing's small size and lightweight nature make it suitable for use in miniature actuators or other precision - motion components.

| Part Number | S681 |

| System of Measurement | Metric |

| Bearing Type | Ball |

| For Load Direction | Radial |

| Construction | Single Row |

| Inner Ring Type | Standard |

| Seal Type | Open |

| Bore Dia | 1 mm |

| Bore Dia Tolerance | -0.008mm to 0 |

| Outer Dia | 3 mm |

| Outer Dia Tolerance | -0.008mm to 0 |

| Width | 1 mm |

| Width Tolerance | -0.12mm to 0 |

| Ring Material | Stainless Steel |

| Ball Material | Stainless Steel |

| Cage Material | Stainless Steel |

| Dynamic Radial Load | 17 lbf |

| Static Radial Load | 4 lbf |

| Max Speed (X1000 rpm) | 117 |

| Lubrication | Required |

| Temperature Range | -30° to 110°C |

| Tolerance Class | ABEC1 |

| Radial Clearance Trade No | MC3 |

| Radial Clearance | 0.005mm to 0.01 mm |

| RoHS | Compliant |

| REACH | Compliant |

| Ball Dia | 0.6 mm |

| Ball Qty | 6 |

| Weight | 0.03 g |