Welcome to TIK Bearing Manufacturing Co., Ltd

PRODUCTS

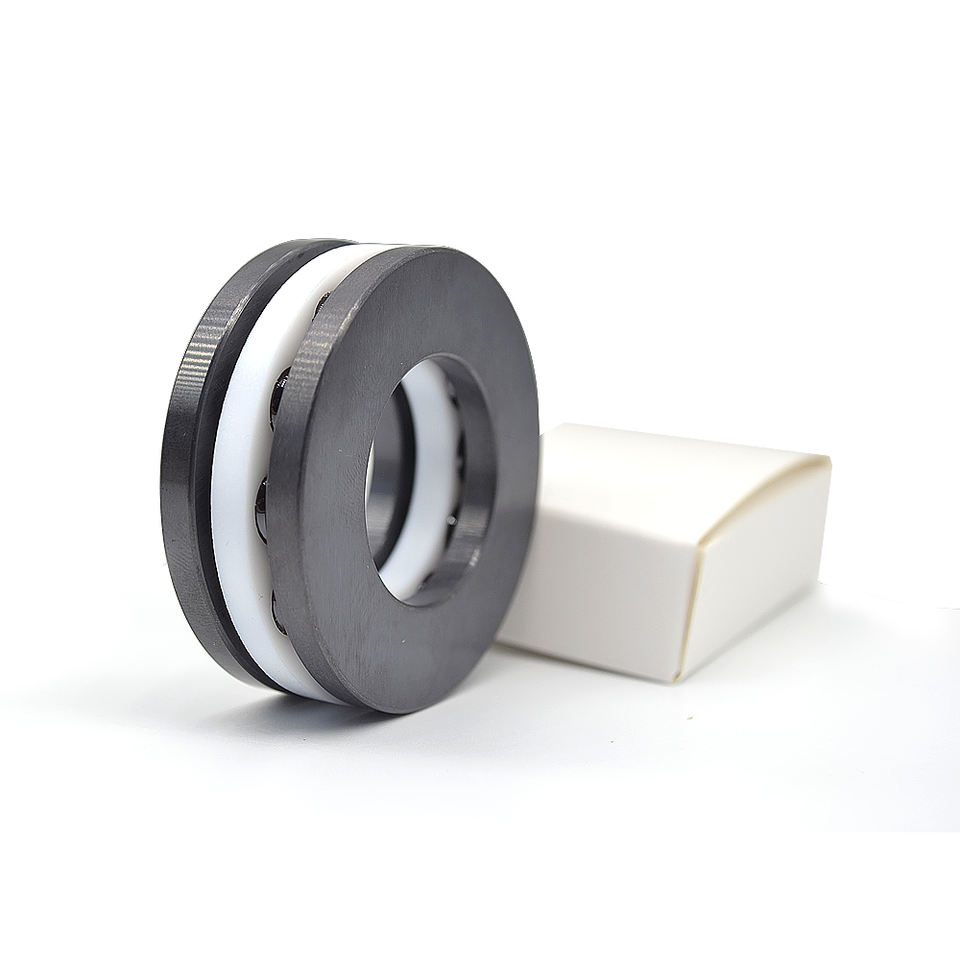

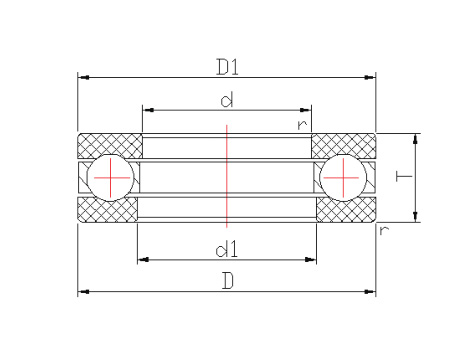

Deep Groove Ball BearingSelf-aligning Ball BearingAngular Contact Ball BearingThrust Ball BearingTapered Roller BearingSpherical Roller BearingCylindrical Roller BearingSpherical Roller Thrust BearingCylindrical Roller Thrust BearingNeedle Roller BearingPillow Block BearingPlummer Block HousingAdapter Sleeve & Withdrawal SleeveSpherical Plain Bearing & Rod EndLinear Motion Ball BearingAuto BearingAgricultural BearingStainless Steel BearingFull Ceramic BearingSteel BallSpecial Bearing